SOLVENT DEGREASER

WITH ULTRA-FAST EVAPORATION

12 MINUTES AT 20°C (ZERO AIR FLOW)

DEVELOPED AS A SUBSTITUTE FOR TRI 111 ETHANE IN ITS COLD APPLICATIONS

INDUSTRIAL MAINTENANCE AND PRECISION MECHANICS DEGREASING

CLEANING BETWEEN OPERATIONS WITH SHORT PROCESS TIMES

SURFACE PREPARATION BEFORE TREATMENT, DECORATION, BONDING

FLASHPOINT NOT MEASURABLE

GUARANTEED FREE FROM GREENHOUSE

FLUORINATED COMPOUNDS WITH A GWP above 150

EU Regulation 517/2014 F. Gas Directive

Prohibited from 1st January 2018

DESCRIPTION

NEUTRALENE® 2012 is a degreaser specifically used to eliminate oils and greases.

NEUTRALENE® 2012 has been formulated in a technology flash point not measurable, and offers more security in the industry. His evaporation rate is particularly suitable for the product has a cleansing action optimal, while evaporating as quickly as possible.

NEUTRALENE® 2012 leaves no residues. This is an excellent agent for preparing surfaces before treatment (paints, collage).

NEUTRALENE® 2012 is compatible with all metals, some plastics and elastomers. It contains no stabilizer, which prevents any further oxidation problem.

NEUTRALENE® 2012 is used pure, cold, with any manual or industrial process.

APPLICATIONS

Cleaner / Degreaser

Excellent solvent for greases, oils, temporal protection product, waxes :

Degreasing of metal parts (aluminum, steel, stainless steel, brass, cast…)

Cleaning of injection molds

Slides degreasing of machine tools.

Degreasing after machining processing

Surface’s preparation

Removes organic or inorganic pollutions before assembling or before surface treatment

(collage, paints…)

Industrial maintenance

For cleaning and degreasing packaging equipment or handling.

Cleaning of workplaces

Degreasing of machines

PRECAUTION OF USE

Before utilization, look at the MSDS. Remove all ignition sources, more particularly, do not

use onto an incandescent object or hot source. Do not use vapor. Avoid splashing onto fabrics to avoid the effects of wick. Do not smoke. Do not allow the drain after use. Use in ventilated area.

RECOMMANDATIONS

Regarding to the diversity of substrates, and more particularly thermoplastics or thermosets

used in industries, we recommend operators to perform any tests of compatibility with sensitive

materials washing and degreasing.

These compatibilities often depend procedures and therefore the contact time between

solvent and plastic materials.

TYPICAL PHYSICAL-CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Fluid |

- |

|

Colour |

Visual |

Colourless |

- |

|

Scent |

Olfactory |

Low |

- |

|

Density at 25°C |

NF EN ISO 12185 |

765 |

kg/m3 |

|

Refraction index |

ISO 5661 |

1.4120 |

- |

|

Freezing point |

ISO 3016 |

-60 |

°C |

|

Water solubility |

- |

0 |

% |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

0.76 |

mm²/s |

|

Acid index |

EN 14104 |

< 0.1 |

mg(KOH)/g |

|

Iodine index |

NF EN 14111 |

nm |

gI2/100g |

|

Water content |

NF ISO 6296 |

< 0.004 |

% |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

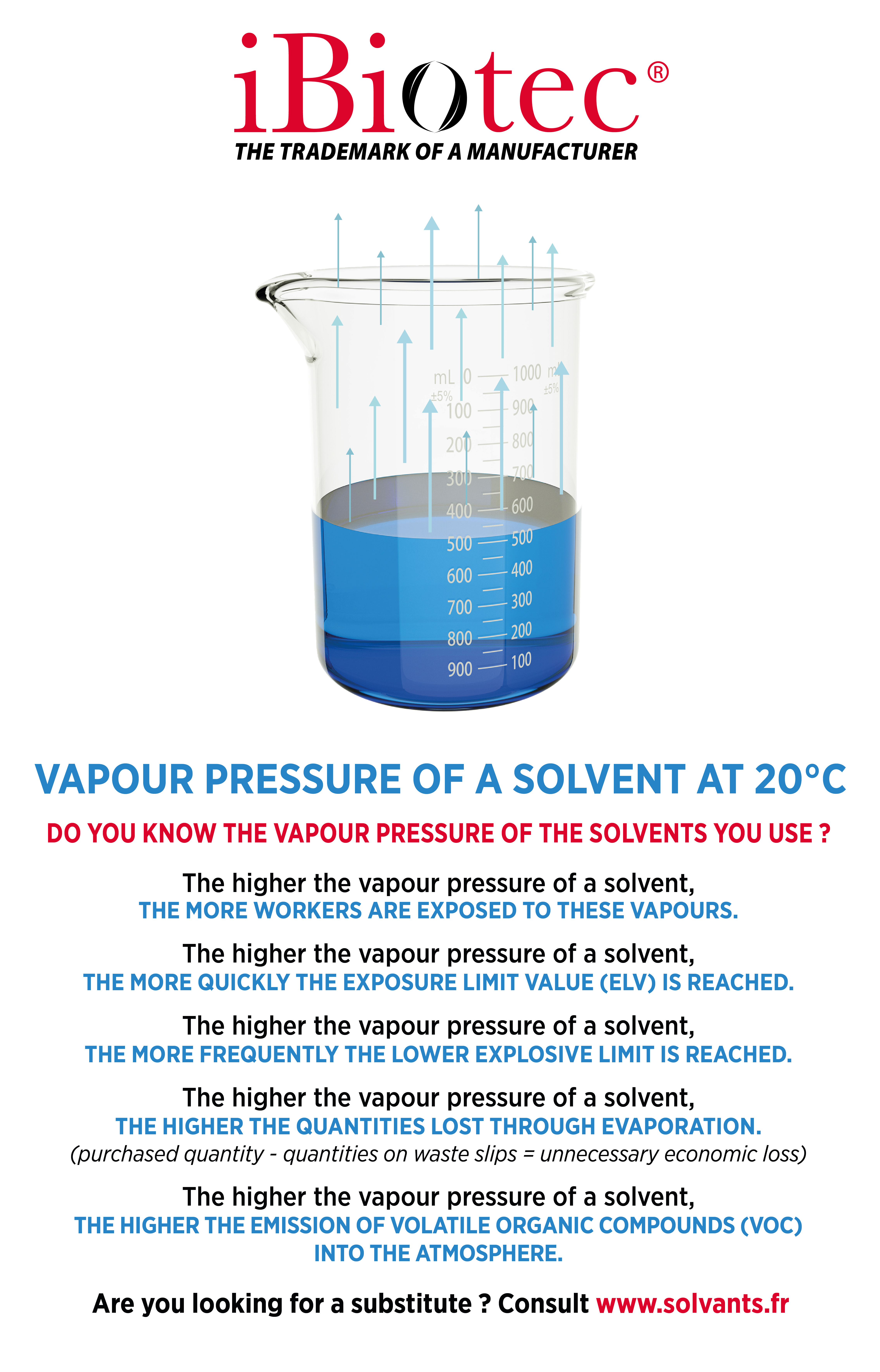

Steam pressure at 20°C |

NF EN 13016-1 |

> 0.01 |

hPa |

|

PERFORMANCE PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

64 |

- |

|

Evaporation speed |

- |

12 |

min. |

|

Surface tension at 20°C |

ISO 6295 |

24.8 |

dyne/cm |

|

Breakdown voltage |

NF EN 60156/IEC 156 |

nm |

Volts |

|

Copper blade corrosion 100 h at 40°C |

ISO 2160 |

1a |

Measured value |

|

FIRE SAFETY PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flashpoint (closed tank) |

ISO 2719 |

not measurable |

°C |

|

Self-combustion point |

ASTM E 659 |

> 250 |

°C |

|

Lower Explosive Limit |

NF EN 1839 |

0.6 |

% (volume) |

|

Upper Explosive Limit |

NF EN 1839 |

7.0 |

% (volume) |

|

Explosive, oxidising agent, flammable, highly or extremely flammable substance content |

CLP Regulation |

- |

% |

|

TOXICOLOGICAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Anisidine index |

NF ISO 6885 |

< 1 |

- |

|

Peroxide index |

NF ISO 3960 |

< 1 |

meq(O2)/kg |

|

TOTOX (anisidine index+2x peroxide index) |

- |

2.8 |

- |

|

CMR, irritant and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

Emissions of hazardous compounds, CMR, irritants, corrosive at 160°C |

GC-MS |

0 |

% |

|

ENVIRONMENTAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Biodegradability |

OECD 301 |

nm |

- |

|

Steam pressure at 20°C |

- |

> 0.01 |

hPa |

|

VOC content (Volatile Organic Compounds) |

- |

100 |

% |

|

Sulphur content |

GC MS |

0 |

% |

|

Benzene content |

ASTM D6229 |

0 |

% |

|

Total halogen content |

GC MS |

< 1 |

% |

|

Chlorinated solvent content |

- |

0 |

|

|

Aromatic solvent content |

- |

0 |

|

|

Environmentally-hazardous substance content |

CLP Regulation |

0 |

% |

|

Content of compounds with GWP |

- |

< 1 |

% |

|

Content of compounds with ODP |

- |

0 |

% |

|

Carbon assessment, life cycles analysis. |

ISO 14040 |

nm |

Kg carbon equivalent |

PRESENTATIONS

|

Drum 200 L

|

Keg 25 L

|

INSTRUCTIONS FOR USE

|

|

|

|

Degreasing with rag |

Degreasing with brush |

|

|

|

|

Hot or cold immersion tanks |

|

Looking for another product?

|

Discover our entire range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.